Περιγραφή Προϊόντος:

Η Οθόνη από Υφαντό Συρματόπλεγμα είναι ένα ευέλικτο και εξαιρετικά αποδοτικό προϊόν σχεδιασμένο για να καλύπτει τις ποικίλες ανάγκες της βιομηχανικής διήθησης, διαλογής, διαχωρισμού και κοσκινίσματος. Κατασκευασμένο με ακρίβεια, αυτό το υφαντό συρματόπλεγμα διαθέτει έναν τύπο πλέγματος με πτυχωτό σύρμα που εξασφαλίζει ανθεκτικότητα, αντοχή και ανώτερη απόδοση υπό απαιτητικές συνθήκες. Η στιβαρή κατασκευή του το καθιστά ιδανική επιλογή για ένα ευρύ φάσμα βιομηχανιών, συμπεριλαμβανομένων της εξόρυξης, της χημικής επεξεργασίας, της παραγωγής τροφίμων και της επεξεργασίας λυμάτων.

Ένα από τα καθοριστικά χαρακτηριστικά της Οθόνης από Υφαντό Συρματόπλεγμα είναι ο τύπος οπής του, ο οποίος διατίθεται σε τετράγωνες και ορθογώνιες επιλογές. Αυτή η ευελιξία επιτρέπει την προσαρμογή σύμφωνα με συγκεκριμένες απαιτήσεις, διευκολύνοντας τη βέλτιστη κατακράτηση και διαχωρισμό σωματιδίων. Το σχήμα του ανοίγματος είναι σταθερά τετράγωνο, παρέχοντας ομοιόμορφα ανοίγματα που ενισχύουν την αποτελεσματικότητα και την ακρίβεια της διαδικασίας διαλογής. Αυτή η ομοιομορφία είναι ιδιαίτερα σημαντική σε εφαρμογές όπου η ακριβής διήθηση και η σταθερή ποιότητα εξόδου είναι υψίστης σημασίας.

Το υφαντό συρματόπλεγμα κατασκευάζεται χρησιμοποιώντας μεταλλικά σύρματα υψηλής ποιότητας που υφαίνονται σχολαστικά μεταξύ τους. Η τεχνική πτυχωτού συρμάτινου πλέγματος που χρησιμοποιείται στην παραγωγή του όχι μόνο ενισχύει το πλέγμα, αλλά και διασφαλίζει ότι τα σύρματα παραμένουν σταθερά αλληλοσυνδεδεμένα, ακόμη και υπό υψηλή τάση και βαριά φορτία. Αυτή η διαδικασία πτύχωσης συμβάλλει στην εξαιρετική διαστατική σταθερότητα του πλέγματος και στην αντοχή του στην παραμόρφωση, καθιστώντας το μια αξιόπιστη επιλογή για μακροχρόνια χρήση σε βιομηχανικά περιβάλλοντα.

Η Οθόνη από Υφαντό Συρματόπλεγμα χρησιμοποιείται ευρέως σε εφαρμογές δονητικών οθονών. Οι δονητικές οθόνες βασίζονται σε μεγάλο βαθμό στην ικανότητα του πλέγματος να αντέχει τη συνεχή κίνηση και τη μηχανική καταπόνηση χωρίς να διακυβεύεται η δομική του ακεραιότητα. Η οθόνη από πτυχωτό υφαντό συρματόπλεγμα υπερέχει σε αυτόν τον ρόλο παρέχοντας σταθερή απόδοση και μειώνοντας το χρόνο διακοπής λειτουργίας λόγω αστοχίας πλέγματος ή προβλημάτων συντήρησης. Η ανθεκτικότητα και η αντοχή του το καθιστούν απαραίτητο συστατικό των συστημάτων δονητικών οθονών που χρησιμοποιούνται για την ταξινόμηση και τον διαχωρισμό υλικών με βάση το μέγεθος.

Εκτός από τα μηχανικά του πλεονεκτήματα, η Οθόνη από Υφαντό Συρματόπλεγμα προσφέρει εξαιρετική προσαρμοστικότητα στις διαδικασίες διήθησης και κοσκινίσματος. Είτε χρησιμοποιείται για τη διήθηση υγρών, τον διαχωρισμό στερεών ή το κοσκίνισμα κοκκωδών υλικών, τα σχεδιασμένα με ακρίβεια τετράγωνα ανοίγματα επιτρέπουν την αποτελεσματική και αποδοτική επεξεργασία. Αυτή η προσαρμοστικότητα το καθιστά κατάλληλο για διάφορες εφαρμογές, συμπεριλαμβανομένων των μονάδων επεξεργασίας νερού όπου η λεπτή διήθηση είναι κρίσιμη, ή στις βιομηχανίες επεξεργασίας τροφίμων όπου η υγιεινή και η αξιοπιστία είναι απαραίτητες.

Επιπλέον, η ικανότητα της Οθόνης από Υφαντό Συρματόπλεγμα να λειτουργεί σε σκληρά περιβάλλοντα υπογραμμίζει περαιτέρω την αξία της. Μπορεί να κατασκευαστεί από διάφορα μέταλλα και κράματα για την ενίσχυση της αντοχής στη διάβρωση, της αντοχής στη θερμότητα και της χημικής αδράνειας. Αυτό διασφαλίζει ότι το πλέγμα αποδίδει βέλτιστα σε περιβάλλοντα που εκτίθενται σε χημικά, ακραίες θερμοκρασίες ή λειαντικές ουσίες, επεκτείνοντας τη διάρκεια ζωής του πλέγματος και μειώνοντας το κόστος αντικατάστασης.

Μια άλλη αξιοσημείωτη εφαρμογή της Οθόνης από Υφαντό Συρματόπλεγμα είναι στις διαδικασίες διαχωρισμού όπου απαιτείται ακριβής ταξινόμηση σωματιδίων. Βιομηχανίες όπως η εξόρυξη και η επεξεργασία ορυκτών εξαρτώνται από αυτές τις οθόνες για τον αποτελεσματικό διαχωρισμό πολύτιμων ορυκτών από τα απόβλητα υλικά. Το τετράγωνο σχήμα του ανοίγματος και ο σχεδιασμός του πτυχωτού σύρματος διευκολύνουν τη γρήγορη διέλευση μικρότερων σωματιδίων, διατηρώντας παράλληλα τα μεγαλύτερα, βελτιστοποιώντας την απόδοση επεξεργασίας και την ποιότητα του προϊόντος.

Συνοψίζοντας, η Οθόνη από Υφαντό Συρματόπλεγμα είναι μια λύση διαλογής υψηλής απόδοσης που χαρακτηρίζεται από την κατασκευή της από πτυχωτό συρμάτινο πλέγμα, το τετράγωνο σχήμα του ανοίγματος και τη διαθεσιμότητα σε τετράγωνους ή ορθογώνιους τύπους οπών. Είναι ειδικά σχεδιασμένο για ένα ευρύ φάσμα εφαρμογών, όπως διήθηση, διαλογή, διαχωρισμός και κοσκίνισμα. Η συμβατότητά του με τα συστήματα δονητικών οθονών υπογραμμίζει την αντοχή και την ανθεκτικότητά του σε δυναμικά περιβάλλοντα λειτουργίας. Είτε χρησιμοποιείται σε βαριές βιομηχανικές διεργασίες είτε σε εργασίες λεπτής διήθησης, η οθόνη από υφαντό συρματόπλεγμα προσφέρει απαράμιλλη αξιοπιστία, αποτελεσματικότητα και μακροζωία, καθιστώντας την ένα απαραίτητο συστατικό στη σύγχρονη επεξεργασία και διαχείριση υλικών.

Χαρακτηριστικά:

-

Όνομα προϊόντος: Οθόνη από Υφαντό Συρματόπλεγμα

-

Σχήμα Ανοίγματος: Τετράγωνο

-

Μέγεθος ματιών: 10-24 Mesh, κατάλληλο για διάφορες ανάγκες φιλτραρίσματος και διαλογής

-

Επιλογές επιφανειακής επεξεργασίας: Γαλβανισμένο, με επίστρωση PVC, Ηλεκτρο-γυαλισμένο για ενισχυμένη ανθεκτικότητα και αντοχή στη διάβρωση

-

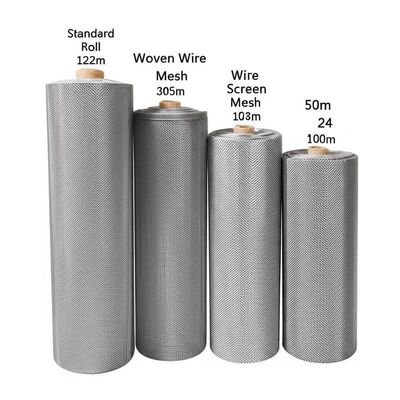

Τυπικά μεγέθη ρολού: 1,0m x 30m/50m/100m και 1,22m x 30,5m/50m/100m για να ταιριάζουν σε διαφορετικές απαιτήσεις εφαρμογής

-

Έκθεση δοκιμής: Διαθέσιμη για διασφάλιση της ποιότητας και της απόδοσης του προϊόντος

-

Ιδανικό για χρήση σε εφαρμογές δονητικών οθονών λόγω της αντοχής και της ακρίβειάς του

-

Η ανθεκτική κατασκευή της οθόνης από υφαντό συρματόπλεγμα παρέχει αξιόπιστα και σταθερά αποτελέσματα διαλογής

-

Η ευέλικτη οθόνη από υφαντό συρματόπλεγμα κατάλληλη για βιομηχανική, γεωργική και εμπορική χρήση

Τεχνικές παράμετροι:

|

Όνομα προϊόντος

|

Οθόνη από Υφαντό Συρματόπλεγμα

|

|

Υφαντός τύπος

|

Απλή ύφανση

|

|

Τυπικό μέγεθος ρολού

|

1,0m*30m/50m/100m, 1,22m*30,5m/50m/100m

|

|

Εφαρμογή

|

Διήθηση, Διαλογή, Διαχωρισμός, Κοσκίνισμα (συμπεριλαμβανομένων δονητικών οθονών και οθονών θραυστήρα πέτρας)

|

|

Επιφανειακή επεξεργασία

|

Γαλβανισμένο, με επίστρωση PVC, Ηλεκτρο-γυαλισμένο, Γυάλισμα

|

|

Mesh

|

18×16, 18×14

|

|

Τύπος οπής

|

Τετράγωνο ή Ορθογώνιο

|

|

Τύπος

|

Πτυχωτό συρματόπλεγμα

|

Εφαρμογές:

Η Οθόνη από Υφαντό Συρματόπλεγμα Kingdelong, με αριθμό μοντέλου KDL, είναι ένα προϊόν υψηλής ποιότητας καταγωγής από την Κίνα, σχεδιασμένο για να καλύπτει τις αυστηρές απαιτήσεις διαφόρων βιομηχανικών εφαρμογών. Πιστοποιημένο με ISO9001, ISO14001, ISO45001 και SGS, αυτή η οθόνη από υφαντό συρματόπλεγμα εγγυάται εξαιρετική ανθεκτικότητα και αξιοπιστία. Με ελάχιστη ποσότητα παραγγελίας 30 τ.μ. και ανταγωνιστικό εύρος τιμών από $75 έως $110, η Kingdelong προσφέρει μια εξαιρετική ισορροπία μεταξύ οικονομικής απόδοσης και ανώτερης απόδοσης. Το προϊόν συσκευάζεται προσεκτικά, τυλιγμένο γύρω από ένα χάρτινο σωλήνα με αδιάβροχο χαρτί ή πλαστικά υφάσματα και διατίθενται προσαρμοσμένες επιλογές συσκευασίας για να ταιριάζουν σε συγκεκριμένες απαιτήσεις πελατών.

Χρησιμοποιείται κυρίως ως οθόνη θραυστήρα πέτρας, η Οθόνη από Υφαντό Συρματόπλεγμα Kingdelong είναι ιδανική για εργασίες διαλογής βαρέως τύπου σε βιομηχανίες εξόρυξης, λατομείων και αδρανών υλικών. Η απλή κατασκευή ύφανσης εξασφαλίζει εξαιρετική αντοχή και αντοχή στη φθορά, καθιστώντας την ιδανική για τον διαχωρισμό λίθων, χαλικιών και άλλων χονδροειδών υλικών. Η διαμόρφωση τετράγωνου ή ορθογώνιου τύπου οπής επιτρέπει την ακριβή ταξινόμηση και διαλογή, βελτιστοποιώντας την απόδοση των δονητικών οθονών και του εξοπλισμού σύνθλιψης.

Εκτός από τη σύνθλιψη πέτρας, αυτή η οθόνη από υφαντό συρματόπλεγμα χρησιμεύει ως κρίσιμο συστατικό σε διάφορες εφαρμογές δονητικών οθονών. Η γυαλισμένη επιφανειακή επεξεργασία της μειώνει την πρόσφυση και τη φθορά του υλικού, ενισχύοντας τη διάρκεια ζωής και την απόδοση της οθόνης κατά τη διάρκεια συνεχούς δόνησης. Τα τυπικά μεγέθη ρολού όπως 1,0m επί 30m/50m/100m και 1,22m επί 30,5m/50m/100m διευκολύνουν την εύκολη εγκατάσταση και αντικατάσταση σε υπάρχουσες μηχανές διαλογής. Το πλέγμα συσκευάζεται με ασφάλεια σε παλέτες για να εξασφαλιστεί η ασφαλής παράδοση εντός 5 έως 7 ημερών εάν είναι σε απόθεμα, με την υποστήριξη ευέλικτων όρων πληρωμής, συμπεριλαμβανομένων D/P, T/T και D/A.

Η οθόνη από υφαντό συρματόπλεγμα Kingdelong χρησιμοποιείται ευρέως σε βιομηχανίες όπως η εξόρυξη, η κατασκευή, η μεταλλουργία και η χημική επεξεργασία. Ο στιβαρός σχεδιασμός και η υψηλή ικανότητα προμήθειας έως και 10.000 τ.μ. το καθιστούν μια αξιόπιστη επιλογή για μεγάλα έργα που απαιτούν αποτελεσματικό διαχωρισμό και διαλογή υλικών. Είτε για νέες εγκαταστάσεις είτε για συντήρηση δονητικών οθονών και εξοπλισμού θραυστήρα πέτρας, η οθόνη από υφαντό συρματόπλεγμα της Kingdelong ξεχωρίζει ως μια αξιόπιστη λύση που συνδυάζει ποιότητα, ανθεκτικότητα και προσιτή τιμή.

Προσαρμογή:

Η Kingdelong προσφέρει προσαρμοσμένα προϊόντα οθόνης από υφαντό συρματόπλεγμα, με αριθμό μοντέλου KDL, σχεδιασμένα για να καλύπτουν τις συγκεκριμένες σας ανάγκες διήθησης, διαλογής, διαχωρισμού και κοσκινίσματος. Κατασκευασμένα στην Κίνα, τα προϊόντα μας είναι πιστοποιημένα με ISO9001, ISO14001, ISO45001 και SGS, εξασφαλίζοντας υψηλή ποιότητα και αξιοπιστία. Το πλέγμα διαθέτει απλή κατασκευή ύφανσης από χάλυβα υψηλού άνθρακα, παρέχοντας εξαιρετικές ιδιότητες κατά της διάβρωσης και ανθεκτικότητα, ιδανικό για εφαρμογές όπως οι εργασίες δονητικών οθονών.

Δεχόμαστε ελάχιστη ποσότητα παραγγελίας 30 τ.μ., με ανταγωνιστικές τιμές που κυμαίνονται από $75 έως $110 ανά τ.μ. Η συσκευασία χειρίζεται προσεκτικά τυλίγοντας το πλέγμα γύρω από ένα χάρτινο σωλήνα πρώτα, στη συνέχεια τυλίγοντάς το με αδιάβροχο χαρτί ή πλαστικά υφάσματα, με προσαρμοσμένες επιλογές συσκευασίας διαθέσιμες κατόπιν αιτήματος.

Η ικανότητα προμήθειας μας φτάνει έως και τα 10.000 τ.μ., και ο χρόνος παράδοσης είναι συνήθως 5 έως 7 ημέρες εάν το προϊόν είναι σε απόθεμα. Οι όροι πληρωμής περιλαμβάνουν D/P, T/T και D/A, προσφέροντας ευελιξία στους πελάτες μας. Η οθόνη από υφαντό συρματόπλεγμα διατίθεται με τετράγωνους ή ορθογώνιους τύπους οπών και διατίθενται εκθέσεις δοκιμών για την εγγύηση της απόδοσης του προϊόντος.

Υποστήριξη και Υπηρεσίες:

Τα προϊόντα μας οθόνης από υφαντό συρματόπλεγμα έχουν σχεδιαστεί για να πληρούν τα υψηλότερα πρότυπα ποιότητας και ανθεκτικότητας, εξασφαλίζοντας βέλτιστη απόδοση σε ένα ευρύ φάσμα βιομηχανικών εφαρμογών.

Εάν χρειάζεστε τεχνική υποστήριξη για την εγκατάσταση, τη συντήρηση ή την αντιμετώπιση προβλημάτων της οθόνης από υφαντό συρματόπλεγμα, η ομάδα των ειδικών μας είναι διαθέσιμη για να σας βοηθήσει με λεπτομερείς οδηγίες και λύσεις προσαρμοσμένες στις συγκεκριμένες σας ανάγκες.

Προσφέρουμε ολοκληρωμένες υπηρεσίες, όπως προσαρμογή προϊόντων, συμβουλές επιλογής υλικών και συστάσεις μεγέθους ματιών για να σας βοηθήσουμε να επιτύχετε τα καλύτερα αποτελέσματα για την εφαρμογή σας.

Για τη συντήρηση, συνιστούμε τακτική επιθεώρηση για φθορά, καθαρισμό για την αποφυγή φραγής και σωστή αποθήκευση για την παράταση της διάρκειας ζωής των οθονών πλέγματος.

Σε περίπτωση προβλημάτων ή ερωτήσεων σχετικά με τις προδιαγραφές του προϊόντος, τη συμβατότητα ή την απόδοση, ανατρέξτε στην τεκμηρίωση του προϊόντος ή συμβουλευτείτε την ομάδα τεχνικής υποστήριξης για άμεση βοήθεια.

Δεσμευόμαστε να παρέχουμε συνεχή υποστήριξη και να διασφαλίζουμε την ικανοποίηση των πελατών με κάθε προϊόν οθόνης από υφαντό συρματόπλεγμα που παραδίδουμε.

Συσκευασία και αποστολή:

Οι οθόνες από υφαντό συρματόπλεγμα συσκευάζονται προσεκτικά για να διασφαλιστεί ότι φτάνουν στην τοποθεσία σας σε άριστη κατάσταση. Κάθε οθόνη τυλίγεται σφιχτά και ασφαλίζεται με προστατευτική περιτύλιξη για την αποφυγή ζημιών κατά τη μεταφορά. Για πρόσθετη προστασία, τα ρολά τοποθετούνται σε ανθεκτικούς χάρτινους σωλήνες ή ξύλινα κιβώτια ανάλογα με το μέγεθος και την ποσότητα που παραγγέλθηκε.

Προσφέρουμε ευέλικτες επιλογές αποστολής για να καλύψουμε τις ανάγκες σας, συμπεριλαμβανομένων αεροπορικών μεταφορών, θαλάσσιων μεταφορών και υπηρεσιών ταχυμεταφορών. Όλες οι αποστολές επιθεωρούνται διεξοδικά πριν από την αποστολή και παρέχονται πληροφορίες παρακολούθησης για να σας ενημερώνουμε για την κατάσταση της παράδοσης. Είτε χρειάζεστε μαζικές παραγγελίες είτε μικρότερες ποσότητες, διασφαλίζουμε την έγκαιρη και ασφαλή παράδοση των οθονών από υφαντό συρματόπλεγμα.

Συχνές ερωτήσεις:

Ε1: Ποιο είναι το εμπορικό σήμα και ο αριθμός μοντέλου αυτής της οθόνης από υφαντό συρματόπλεγμα;

Α1: Το εμπορικό σήμα είναι Kingdelong και ο αριθμός μοντέλου είναι KDL.

Ε2: Πού κατασκευάζεται η οθόνη από υφαντό συρματόπλεγμα;

Α2: Κατασκευάζεται στην Κίνα.

Ε3: Τι πιστοποιήσεις έχει η οθόνη από υφαντό συρματόπλεγμα;

Α3: Το προϊόν κατέχει πιστοποιήσεις ISO9001, ISO14001, ISO45001 και SGS.

Ε4: Ποια είναι η ελάχιστη ποσότητα παραγγελίας και το εύρος τιμών για αυτό το προϊόν;

Α4: Η ελάχιστη ποσότητα παραγγελίας είναι 30 τετραγωνικά μέτρα και η τιμή κυμαίνεται από $75 έως $110 ανά τετραγωνικό μέτρο.

Ε5: Πώς συσκευάζεται το προϊόν και ποιος είναι ο χρόνος παράδοσης;

Α5: Η οθόνη πλέγματος συσκευάζεται τυλίγοντας γύρω από ένα χάρτινο σωλήνα, τυλιγμένο με αδιάβροχο χαρτί ή πλαστικά υφάσματα. Διατίθεται επίσης προσαρμοσμένη συσκευασία. Ο χρόνος παράδοσης είναι συνήθως 5 έως 7 ημέρες εάν το προϊόν είναι σε απόθεμα.

Ε6: Ποιοι όροι πληρωμής γίνονται δεκτοί για την αγορά της οθόνης από υφαντό συρματόπλεγμα;

Α6: Οι αποδεκτοί όροι πληρωμής περιλαμβάνουν D/P, T/T και D/A.

Ε7: Ποια είναι η ικανότητα προμήθειας της Kingdelong για την οθόνη από υφαντό συρματόπλεγμα;

Α7: Η Kingdelong μπορεί να προμηθεύσει έως και 10.000 τετραγωνικά μέτρα.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!